Nordic Fender supplies all sorts of profile fenders, in rubber or foam/PU.

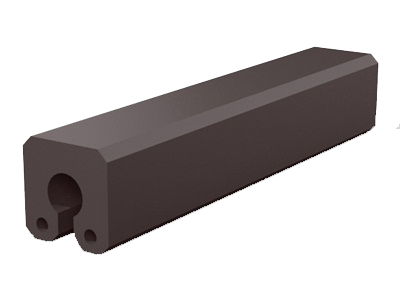

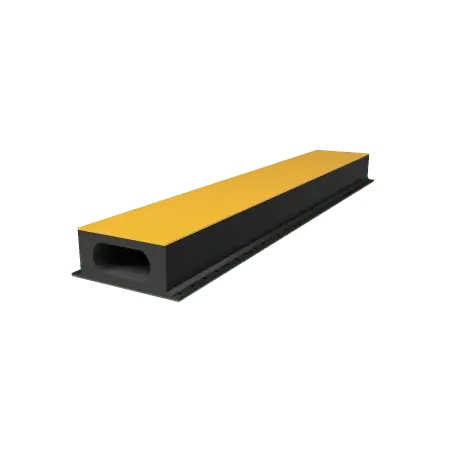

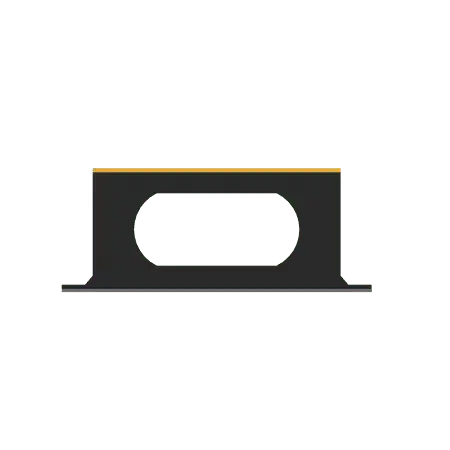

D Fender

Robust fender for many different applications such as quay walls and jetties, plus installed on vessels typically as a fender list. Can be delivered with D-bore or circular bore (O), cut to specific lengths and pre-drilled in case needed.

Cylindrical Fender

Probably the most common type to find in smaller ports and harbours around the world. Can also be used on ships for various type of operations. With the hollow cylindrical shape it easy to install, and with a range starting from 100 mm OD (diameter) up to 2500 it can be a good alternative for many different segments.

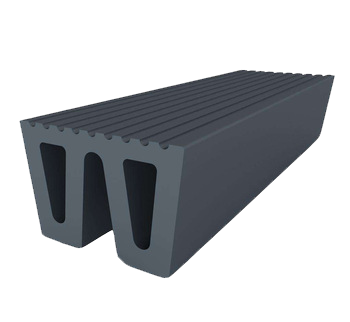

Keyhole Fender

Probably the most common type to find in smaller ports and harbours around the world. Can also be used on Common to find on tugs, installed in the bow and stern, offering proper protection for heavy duty operations. They are also seen on special installations such as ramps in ports, and pontoons. There are various optional features such as flat/ribbed face, solid block +.

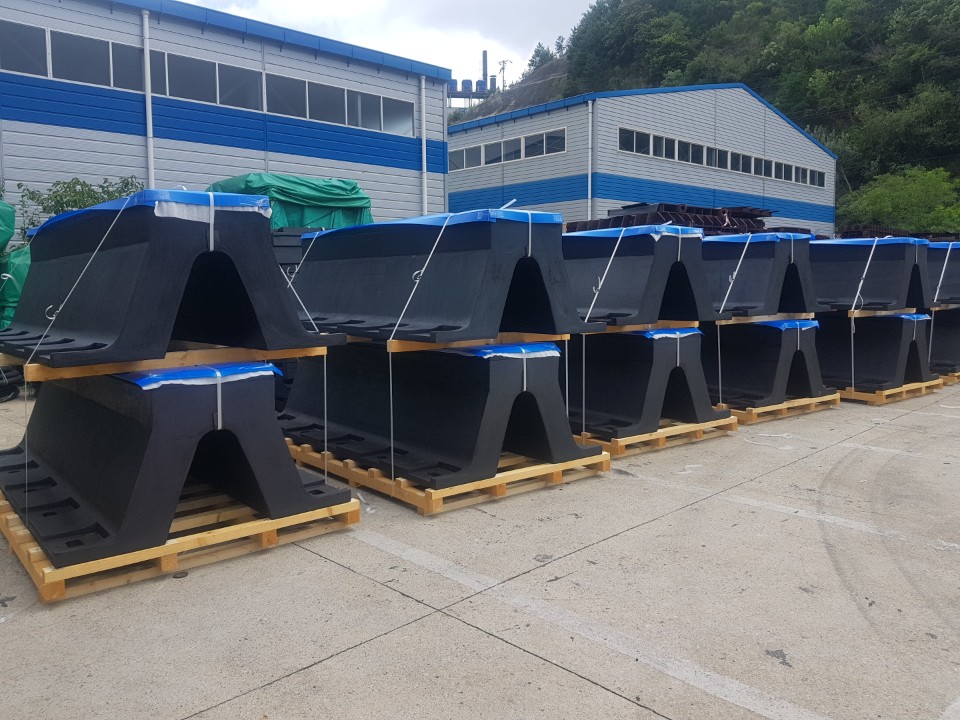

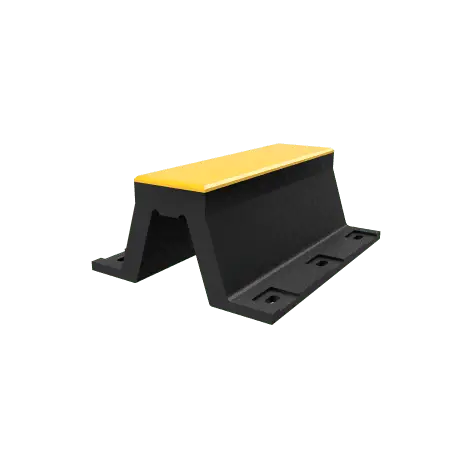

W/M Fender

The W and M fenders are commonly used on tugs. These are moulded rubber units made to tolerate tough operations, with tugs using the bow and stern actively in the daily operations. Sizes from 320 mm to 500 mm.

Element Fender

The element fender consist of legs, with internal steel mounting plates and concealed bolts. These are used in ports, and can be installed as a V fender with UHMW-PE pad or more complex arrangements.

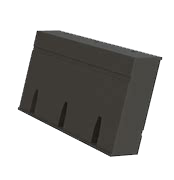

Arch Fender

Arch fenders are either rubber faced or with UHMW-PE padding. Typical to find on quay walls, offering minimal maintenance and wide range of sizes are available. Can also be found on special ships such as FPSO, installed on specific area on the hull for protection of critical equipment.

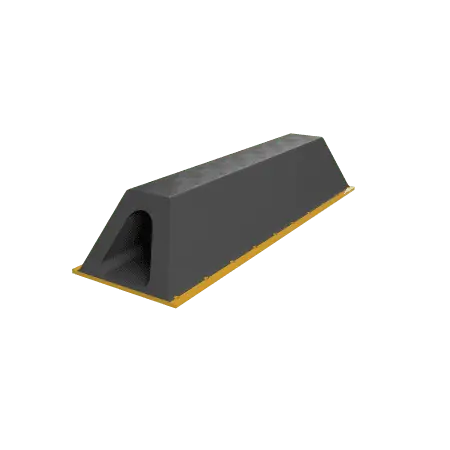

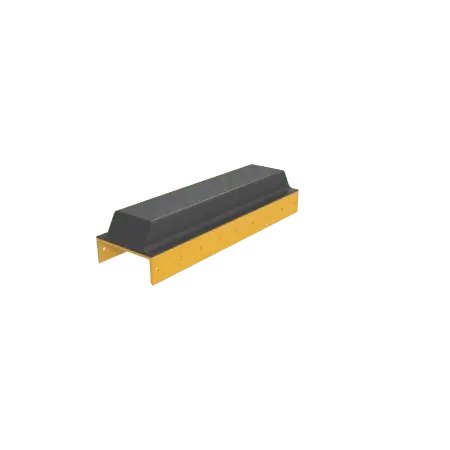

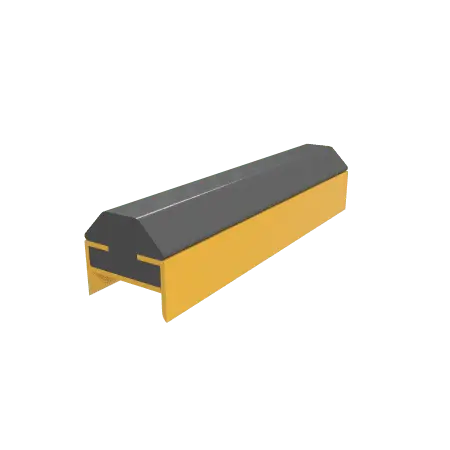

Rubbing strips

Rubbing strips are premium, abrasion-resistant rubber components with steel backing, designed for durability and robust performance. They serve to shield offshore jacket legs or boat landings from impacts and wear, significantly extending their lifespan. Engineered for harsh offshore conditions, these strips feature exceptional shear strength. Nordic Fender offers a range of rubbing strips tailored to different loads and applications.

Type of rubbing strips: Jacket leg rubbing strip, boat landing rubbing strips-type, boat landing rubbing strips (several types) and D-type boat landing rubbing fender.

Read more on our offshore section, here.

Sway and surge fender

Surge and sway fenders are crucial in float-over operations for installing offshore topsides. They absorb impacts between the barge and offshore structure, preventing damage and limiting movement. Special rubber compounds are used for these applications.

Read more in our offshore section, here.

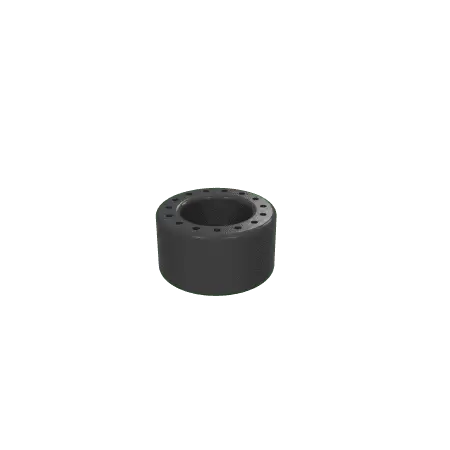

Bumper rings

Bumper Rings are an integral component of Barge Bumpers, designed to absorb and dissipate berthing energy while rotating on the Contact Post of the Barge Bumpers. This rotating action minimizes the shear force exerted by the rubbing of barges or boats during berthing. These rings are highly versatile, finding extensive application across various Barge Bumper Assemblies and configurations. Depending on specific duty requirements and operational conditions, Bumper Rings can be tailored to meet different functions and specifications. They can also be supplied in highly abrasive-resistant polyurethane rubber.

Read more in our offshore section, here.

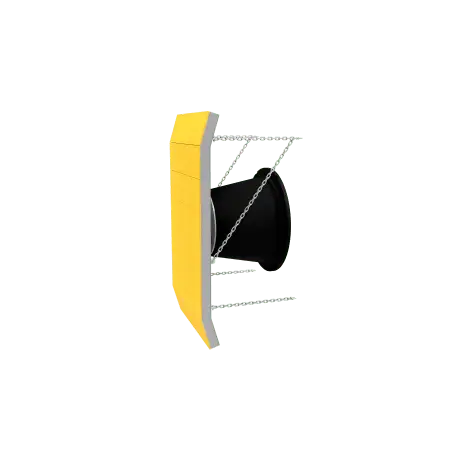

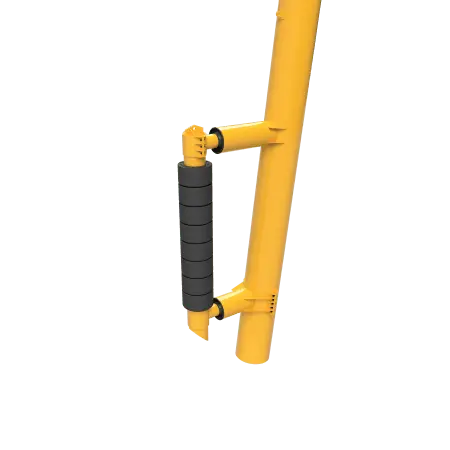

Barger bumpers

Barge bumper system is designed to absorb the berthing energy of barges and tugs at offshore rigs. The system consists of two shock cells and a bumper post with revolving rubber rings, which together allow for both axial and horizontal load absorption, making it ideal for challenging offshore conditions.

There are two types of barge bumpers: one with a basic shock cell and another with an eccentric bumper ring attached to the shock cell. The latter configuration reduces point load stress on the bumper post and steel components, supporting higher loads.

We also work with first class manufacturer of system fenders, for ports and terminals. We can offer a complete package and support – from initial project phase to final installation.