When you need equipment designed to withstand extreme and hazardous conditions, Nordic Fender has you covered.

Pneumatic fenders

Our Pneumatic Fenders are first class fenders manufactured in full compliance with ISO 17357-1:2014. We promise outstanding performance and durability, supporting you in running a safe operation – on time!

Range:

- Chain & tire net fenders (Sizes from 1,0 m x 1,5 m to 4,5 m x 9,0 m)

- Sling fenders (Sizes from 0,5 m x 1,0 m to 4,5 m x 9,0 m)

Optional features:

- Heavy duty aircraft tyre net

- Special colors, both fender body and tyre net

- GPS and internal pressure sensor – monitoring device

- Other special sizes on request

Rubbing strips

Rubbing strips are premium, abrasion-resistant rubber components with steel backing, designed for durability and robust performance. They serve to shield offshore jacket legs or boat landings from impacts and wear, significantly extending their lifespan. Engineered for harsh offshore conditions, these strips feature exceptional shear strength.

Nordic Fender offers a range of rubbing strips tailored to different loads and applications.

Features:

- Specially formulated low-friction rubber

- Custom backing plates that can be welded or bolted to the jacket leg

- Special UHMWPE bonded rubbing strip available

- Virtually maintenance free

- Easy to install

Applications:

- Offshore jacket legs

- Boat landing

- Jetty walls

- Jetty legs

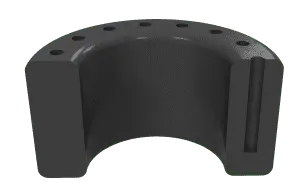

Surge and sway fender

Surge and sway fenders are crucial in float-over operations for installing offshore topsides. They absorb impacts between the barge and offshore structure, preventing damage and limiting movement. Special rubber compounds are used for these applications.

Features:

• Protects the jacket and transport barge during float-over operation

• Safely absorbs the berthing loads

• Decreases relative movement of the barge

• smother mating operation

• Easy to install and remove after float over operation

Applications:

• Offshore platform jacket structure

• Transportation barge

• Offshore Wind jackets

• Decommissioning of topside

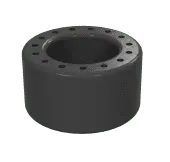

Bumper rings

Bumper Rings are an integral component of Barge Bumpers, designed to absorb and dissipate berthing energy while rotating on the Contact Post of the Barge Bumpers. This rotating action minimizes the shear force exerted by the rubbing of barges or boats during berthing. These rings are highly versatile, finding extensive application across various Barge Bumper Assemblies and configurations. Depending on specific duty requirements and operational conditions, Bumper Rings can be tailored to meet different functions and specifications. They can also be supplied in highly abrasive-resistant polyurethane rubber.

Features:

- Special interlocking design

- Multiple cavities in rings allow for better load absorption

- The geometry will allow the rotation of rings on the bumper post

- High abrasion and tear-resistant rubber compound

Applications:

- Part of the bumper post

- Jetty piles

- Offshore structures

Barger bumpers

Barge bumper system is designed to absorb the berthing energy of barges and tugs at offshore rigs. The system consists of two shock cells and a bumper post with revolving rubber rings, which together allow for both axial and horizontal load absorption, making it ideal for challenging offshore conditions.

There are two types of barge bumpers: one with a basic shock cell and another with an eccentric bumper ring attached to the shock cell. The latter configuration reduces point load stress on the bumper post and steel components, supporting higher loads.

Features:

- Capable of absorbing both axial and lateral loads

- Virtually maintenance free

- Can be deployed in areas with high tidal variations

- The specially designed bumper post will allow smooth and even load distribution

- Rotating bumper rings will rotate upon impact thus eliminating point abrasions

Applications:

• Offshore Platforms

• Drilling Platforms

Shock cells

Shock cells are specialized shock absorbers designed to protect offshore platforms. Each shock cell features a highly resilient rubber element sandwiched between two eccentric steel tubes.

These shock cells excel in both lateral and axial deflection, absorbing significant energy with minimal reaction force. Their compact design and versatility make them ideal for offshore use.

To enhance energy absorption and integration with barge bumpers, shock cells can be fitted with an eccentric bumper ring. Nordic Fender offers shock cells in various tube sizes and lengths to accommodate different load scenarios and pile diameters.

Features:

- Excellent lateral and axial load absorption capability

- Can be supplied with a flange to easily install on the offshore jacket

- Small footprint thus ideal for offshore application

- Can be supplied with an EBR

- each shock cell can be load tested at full scale at out testing facility

- Easy installation

Applications:

- Offshore Platform Jackets

- Offshore wind farms

- Boat landing

- Barge bumper

Deck support unit

Deck support units (DSUs) are sliding supports commonly used on topside structures and barge legs. A DSU features a rubber element with a sliding material on top, designed for low friction. When the topside leg rests on the DSU, the rubber element compresses to a set limit, creating a secure connection that prevents lateral movement during transit. This setup facilitates load transfer from the topside leg to the load management unit (LMU) during float-over operations. Once the load transfer is complete, the DSU’s sliding surface ensures smooth movement of the barge.

Features:

• Supports topside placed on an integrated deck frame

• Allows horizontal movement between topside and barge

• Lower risk of damage during adverse weather in transportation

• Allow horizontal movement between the topside and deck support frame during and after the mating process

• Customized rubber compounds for custom load requirements

• Full-scale testing compression at our in-house testing facility

Applications:

• Offshore float-over operation

• Offshore terminal construction

• Offshore wind fam topsides

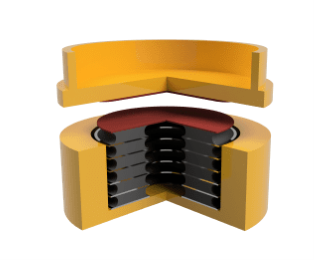

Leg mating units

Leg mating units (LMUs) are essential for offshore floatover operations. During these operations, the barge is positioned over the jacket legs, with the LMUs already attached to either the jacket or topside legs. The LMU receptor cone aligns with the jacket cone, and ballasting lowers the topside onto the legs. This process, performed in open sea, requires the LMUs to absorb both vertical and horizontal loads.

Each LMU includes specially formulated vertical and horizontal rubber elements designed to handle heavy loads with minimal creep. Once the topside load transfer is complete, and the structure is secure, the sand can be released from the sand release valve, lowering the plunger assembly and releasing the load on the rubber elements.

Nordic Fender offers extensive customization options, including various rubber elements, sand release valves, and horizontal elastomers, tailored to specific project requirements. Our in-house experts design each LMU to meet the unique needs of every project.

Features:

- Custom designed to take immense loads of topsides

- most efficient and cost-effective solution for heavy topsides

- Performs even in adverse weather conditions

- Removes the need for expensive and time-consuming offshore cranes

- An optional sand jack can be manufactured to release the loads on rubber elements

- Different types of rubber elements can be custom-made depending on the load and conditions

- optional stabbing cone assembly can also be supplied

Applications:

- Float-over operation

- Installation of heavy topsides